Dynapump LE Series

Dynapump LE Series

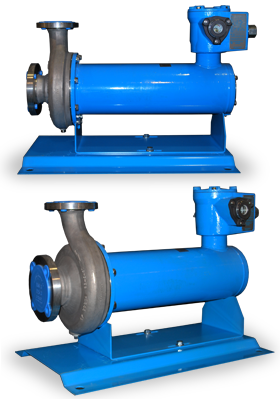

DYNAPUMP LE SERIES

ANSI PUMPS REDEFINED

Seal-less – Revolutionary Dynapump LE Canned Motor Pumps

Now you can get engineered, canned motor pumps at a price comparable to mechanical seal pumps. Dynapump LE Canned Motor Pumps are environmentally friendly. You already know about the benefits of canned motor technology. There’s no reason to spec anything else for your ANSI pump applications.

- Environmentally friendly – It’s the greenest pump you can buy – no leaks…ever!

- Seal-less

- Leakproof – 100% leak-free, double containment surpasses mag drive pumps

- Innovative design keeps the bearings running cooler – greatly increasing service interval time

- Quick availability – Stock to 3 weeks for delivery

Dynapump LE Canned Motor Pumps:

- Totally eliminate hazardous emissions & costly leaks

- Totally eliminate leaking mechanical seals, associated maintenance & costly downtime

- Totally eliminate single containment mag drives

- Totally eliminate mag drive high cost

FEATURES

- ANSI/ASME B73.3M Compliant – No modifications necessary to the piping, base plate or electrical switchgear when replacing your existing ANSI pump.

- Bearing Wear Detector – Powerful diagnostic tool for monitoring the condition of the pump. Allows users to perform simple parts replacement well before significant damage occurs.

- Positive Secondary Containment – Contains the process fluid within the pump.

- Low Cost – Price is comparable to a single mechanical sealed ANSI pump.

- 316SS Construction with Hastelloy C Liners – Offers excellent corrosion resistance for the majority of liquids.

- Carbon Graphite Bearings – Excellent chemical resistance and very forgiving bearings when process upsets occur.

- Field Replaceable Wear Parts – Allows users to perform most repairs in-house.

- Automatic Thrust Balance – Eliminates contact between rotating and stationary elements. The single rotating assembly “floats” in the liquid.

- Best in Class Efficiency – Low & high flow impeller designs for each size.

OPTIONS

- Silicon Carbide Bearing System – For solids handling or enhanced chemical compatibility applications.

- Remote Bearing Wear Indicator – Remote alarm, panel mount or 4 to 20 rnA outputs available for continuous monitoring of pump.

- ThermoWell – Mounted in rear bearing housing for temperature monitoring.

- ANSI Dimensional Baseplates – For drop in replacement.

- Water Jacket – For temperature control.

SPECIFICATIONS

- Design Pressure: 150 PSI

- Motor Size: Up to 16.6 hp.

- Max fluid Temp: -50°F to 275°F

- Viscosity: Up to 100 Centipoise

DYNAPUMP LE SERIES ADVANTAGES

| FEATURES | |

|---|---|

| DIAGNOSTICS | |

| DYNAPUMP LE | BEARING WEAR MONITOR (TRG) |

| MAG DRIVE PUMPS | NONE |

| MECHANICAL SEALED PUMPS | NONE |

| SECONDARY CONTAINMENT | |

| DYNAPUMP LE | YES |

| MAG DRIVE PUMPS | NO |

| MECHANICAL SEALED PUMPS | NO |

| SHAFT ALIGNMENT | |

| DYNAPUMP LE | NOT REQUIRED |

| MAG DRIVE PUMPS | REQUIRED ON POWER FRAME UNITS |

| MECHANICAL SEALED PUMPS | REQUIRED ON POWER FRAME UNITS |

| NUMBER OF BEARINGS | |

| DYNAPUMP LE | ONLY 2 |

| MAG DRIVE PUMPS | 4 TO 6 |

| MECHANICAL SEALED PUMPS | 4 TO 6 |

| NUMBER OF BALL BEARINGS | |

| DYNAPUMP LE | NONE |

| MAG DRIVE PUMPS | 2 TO 4 |

| MECHANICAL SEALED PUMPS | 2 TO 4 |

| NUMBER OF MOVING PARTS | |

| DYNAPUMP LE | ONE |

| MAG DRIVE PUMPS | 2 TO 3 |

| MECHANICAL SEALED PUMPS | 2 TO 3 |

| SIZE (LENGTH) BASED ON DIMENSIONS OF 3X1 1/2 -8 10HP | |

| DYNAPUMP LE | 25.75 INCHES |

| MAG DRIVE PUMPS | 29.5 INCHES (CLOSE COUPLED) 39.5 INCHES (LONG COUPLED UNITS |

| MECHANICAL SEALED PUMPS | 29.5 INCHES (CLOSE COUPLED) 39.5 INCHES (LONG COUPLED UNITS |

| FOUNDATION REQUIREMENTS | |

| DYNAPUMP LE | NONE |

| MAG DRIVE PUMPS | RIGID ON LONG COUPLED UNITS |

| MECHANICAL SEALED PUMPS | RIGID ON LONG COUPLED UNITS |

| SPECIAL TOOLS | |

| DYNAPUMP LE | NONE |

| MAG DRIVE PUMPS | NON FERROUS AREA REQUIRED |

| MECHANICAL SEALED PUMPS | NONE |

| MAINTENANCE SAFETY REQUIREMENTS | |

| DYNAPUMP LE | NONE |

| MAG DRIVE PUMPS | HIGH RISK OF INJURY TO HANDS DUE TO MAGNET ATTRACTION. MAGNETIC FIELD AFFECTS ELECTRICAL DEVICES SUCH AS PACEMAKERS AND MAGNETIC INFORMATION STORED ON CREDIT CARDS, BANK CARDS AND COMPUTER DISKS. |

| MECHANICAL SEALED PUMPS | NONE |

| MOUNTING | |

| DYNAPUMP LE | VERTICAL OR HORIZONTAL |

| MAG DRIVE PUMPS | HORIZONTAL |

| MECHANICAL SEALED PUMPS | HORIZONTAL |

| FEATURES | DYNAPUMP LE | MAG DRIVE PUMPS | MECHANICAL SEALED PUMPS |

| DIAGNOSTICS | BEARING WEAR MONITOR (TRG) | NONE | NONE |

| SECONDARY CONTAINMENT | YES | NO | NO |

| SHAFT ALIGNMENT | NOT REQUIRED | REQUIRED ON POWER FRAME UNITS | REQUIRED ON POWER FRAME UNITS |

| NUMBER OF BEARINGS | ONLY 2 | 4 TO 6 | 4 TO 6 |

| NUMBER OF BALL BEARINGS | NONE | 2 TO 4 | 2 TO 4 |

| NUMBER OF MOVING PARTS | ONE | 2 TO 3 | 2 TO 3 |

| SIZE (LENGTH) BASED ON DIMENSIONS OF 3X1 1/2 -8 10HP | 25.75 INCHES | 29.5 INCHES (CLOSE COUPLED) 39.5 INCHES (LONG COUPLED UNITS | 29.5 INCHES (CLOSE COUPLED) 39.5 INCHES (LONG COUPLED UNITS |

| FOUNDATION REQUIREMENTS | NONE | RIGID ON LONG COUPLED UNITS | RIGID ON LONG COUPLED UNITS |

| SPECIAL TOOLS | NONE | NON FERROUS AREA REQUIRED | NONE |

| MAINTENANCE SAFETY REQUIREMENTS | NONE | HIGH RISK OF INJURY TO HANDS DUE TO MAGNET ATTRACTION. MAGNETIC FIELD AFFECTS ELECTRICAL DEVICES SUCH AS PACEMAKERS AND MAGNETIC INFORMATION STORED ON CREDIT CARDS, BANK CARDS AND COMPUTER DISKS. | NONE |

| MOUNTING | VERTICAL OR HORIZONTAL | HORIZONTAL | HORIZONTAL |

BEARING WEAR MONITOR

A standard feature supplied on all Dynapump LE pumps is Teikoku USA’s patented bearing wear monitor, the Teikoku Rotary Guardian or “TRG”. The TRG takes the mystery out of pump reliability by continuously monitoring the critical running clearances between the rotating and stationary components.

The bearing wear monitor is mounted on the Dynapump LE electrical junction box as standard, and remote output options are also available. This information allows the user to perform planned maintenance and replacement of simple wear parts long before a costly failure occurs.

DIMENSIONS & CURVES

| LIQUID END – MOTOR | SUCT | DISC | A | D | E | F | G | I | J | O | X | WT |

| 0204S(F/G)1 – 3111 (AA-6) | 1.5 | 1 | 15.75 | 5.25 | 0 | 7.25 | 7.5 | 16 | 17.75 | 11.75 | 6.5 | 100 |

| 0204S(F/G)1 – 3115 (AA-6) | 1.5 | 1 | 15.75 | 5.25 | 0 | 7.25 | 7.5 | 18 | 19.75 | 11.75 | 6.5 | 110 |

| 0204S(F/G)1 – 3211 (AA-6) | 1.5 | 1 | 16.25 | 5.25 | 0 | 7.25 | 7.5 | 19.5 | 21.25 | 11.75 | 6.5 | 132 |

| 0204S(F/G)1 – 3215 (AA-6) | 1.5 | 1 | 16.25 | 5.25 | 0 | 7.25 | 7.5 | 23.75 | 25.25 | 11.75 | 6.5 | 176 |

| 0204T(F/G)1 – 3215 (AA-8) | 1.5 | 1 | 16.25 | 5.25 | 0 | 7.25 | 7.5 | 23.75 | 25.25 | 11.75 | 6.5 | 198 |

| 0204T(F/G)1 – 3315 (AA-8) | 1.5 | 1 | 17 | 5.25 | 0 | 7.25 | 7.5 | 28.25 | 30 | 11.75 | 6.5 | 264 |

| 0408S(F/G)1 – 3111 (AB-6) | 3 | 1.5 | 15.75 | 5.25 | 0 | 7.25 | 7.5 | 16 | 18 | 11.75 | 6.5 | 100 |

| 0408S(F/G)1 – 3211 (AB-6) | 3 | 1.5 | 16.25 | 5.25 | 0 | 7.25 | 7.5 | 20 | 21.5 | 11.75 | 6.5 | 132 |

| 0408S(F/G)1 – 3215 (AB-6) | 3 | 1.5 | 16.25 | 5.25 | 0 | 7.25 | 7.5 | 24 | 25.75 | 11.75 | 6.5 | 187 |

| 0408T(F/G)1 – 3311 (A50-8) | 3 | 1.5 | 20 | 8.25 | 7.25 | 12.5 | 8.5 | 24.25 | 25.75 | 16.75 | 8.5 | 231 |

| 0408T(F/G)1 – 3315 (A50-8) | 3 | 1.5 | 19 | 8.25 | 7.25 | 12.5 | 8.5 | 28.5 | 30 | 16.75 | 8.5 | 275 |

| 0508S(F/G)1 – 3211 (A10-6) | 3 | 2 | 19.25 | 8.25 | 7.25 | 12.5 | 8.5 | 20 | 21.5 | 16.5 | 8.25 | 143 |

| 0508S(F/G)1 – 3215 (A10-6) | 3 | 2 | 19.25 | 8.25 | 7.25 | 12.5 | 8.5 | 24.25 | 25.75 | 16.5 | 8.25 | 198 |

| 0508T(F/G)1 – 3311 (A60-8) | 3 | 2 | 20 | 8.25 | 7.25 | 12.5 | 8.5 | 24.5 | 26 | 17.75 | 9.5 | 242 |

| 0508T(F/G)1 – 3315 (A60-8) | 3 | 2 | 20 | 8.25 | 7.25 | 12.5 | 8.5 | 28.5 | 30 | 17.75 | 9.5 | 286 |

All DIMENSIONS IN INCHES. WEIGHT IN LBS.