Isochem

Isochem

ENGINEERED FOR ENVIRONMENTAL SAFETY

ENGINEERED FOR ENVIRONMENTAL SAFETY

Pulsafeeder’s ISOCHEM pumps safely handle hazardous, highly corrosive, explosive, or toxic chemicals. They provide safe, leak-free service because the magnetic coupling eliminated the need for traditional sealing methods, such as mechanical seals or packing, the main source of leakage problems on pumps. As a result, downtime and maintenance costs are greatly reduced. And there are no worn seals to replace.

ISOCHEM Offers Many Benefits:

- Minimizes exposure of your personnel to hazardous chemicals.

- Eliminates contacting seal faces which are prone to wear and leakage.

- Provides superior corrosion resistance and minimizes heating by utilizing a Hastelloy C containment.

- Eliminates costly seal flush systems required on all pumps with double mechanical seals.

- Reduces downtime and maintenance costs through extended service intervals.

- Eliminates alignment problems inherent to direct-coupled units.

Applications

ISOCHEM Series pumps handle a broad range of applications over wide temperature, viscosity, and pressure variations. They are ideal for vacuum service and transfer of expensive, hazardous and/or corrosive chemicals over the entire pH range. Seal-less features makes then perfect for environments subject to federal regulations.

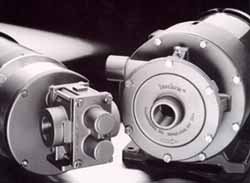

ISOCHEM’S ARE OFFERED IN TWO PRINCIPAL DESIGNS:

GMC Series GEAR pumps – ideal for use when you encounter viscosity or suction lift requirements. They are available in a wide range of materials (316SS, Alloy 20, Hastelloy C, Titanium, Hastelloy B2, and others.).

The ISOCHEM gear pump incorporates many standard features which yields a product that is unsurpassed in quality by other seal-less pump manufacturers. The durability of these mag-drive pumps is unmatched. The numerous material combinations available make ISOCHEM pumps ideal for continuous duty industrial applications over:

- Wide temperature ranges (-99 °F to 450 °F)

- Viscosity ranges (thin fluids – 0.25 cps / viscous fluids – 100,000 cps)

- Pressure variations (differential pressures up to 13.8 bar (200 psig) on certain models)

These self-priming pumps yield a constant volume for a particular drive speed and provide linear pulsation-free flows. They depend only upon fluids pumped for cooling, and are designed with component materials which are inherently self-lubricating.

Reliability

ISOCHEM gear pumps are easy to maintain. All that is required to inspect the internal components is the removal of a single end plate. Therefore, these pumps can be repaired in the field in a matter of minutes – without removal from your system.

CM Series CENTRIFUGAL pumps – available as single- or multi- stage units (up to five stages). They are available in 316 stainless steel, Alloy 20, and Hastelloy C construction as standard for maximum chemical resistance.

The ISOCHEM centrifugal pump was designed with the user in mind. The features found in the CMC and CMH Series provide the user with a safe, leak-free installation and long operating life. Designed with the highest quality materials to help insure maximum operating life under the most demanding process conditions. For example, the advanced bearing design supporting the magnetic assembly utilizes silicon carbide, providing superior wear and corrosion resistance assuring longer life. The numerous material combinations available make ISOCHEM centrifugals ideal for continuous duty industrial applications over:

- Wide temperature ranges (-100°F to 400°F)

- Viscocities to 100 cps

- Flows to 85 gpm, pressures to 156 psi (360 ft)

High Efficiency

Hydraulic efficiency has been raised to a level unmatched in pumps of this size. Precision cast closed impellers and housings reduce flow resistance to a minimum, resulting in lower horsepower requirements.

ENGINEERED FOR

ENGINEERED FOR