Liquid Recovery Systems

Liquid Recovery Systems (LRS)

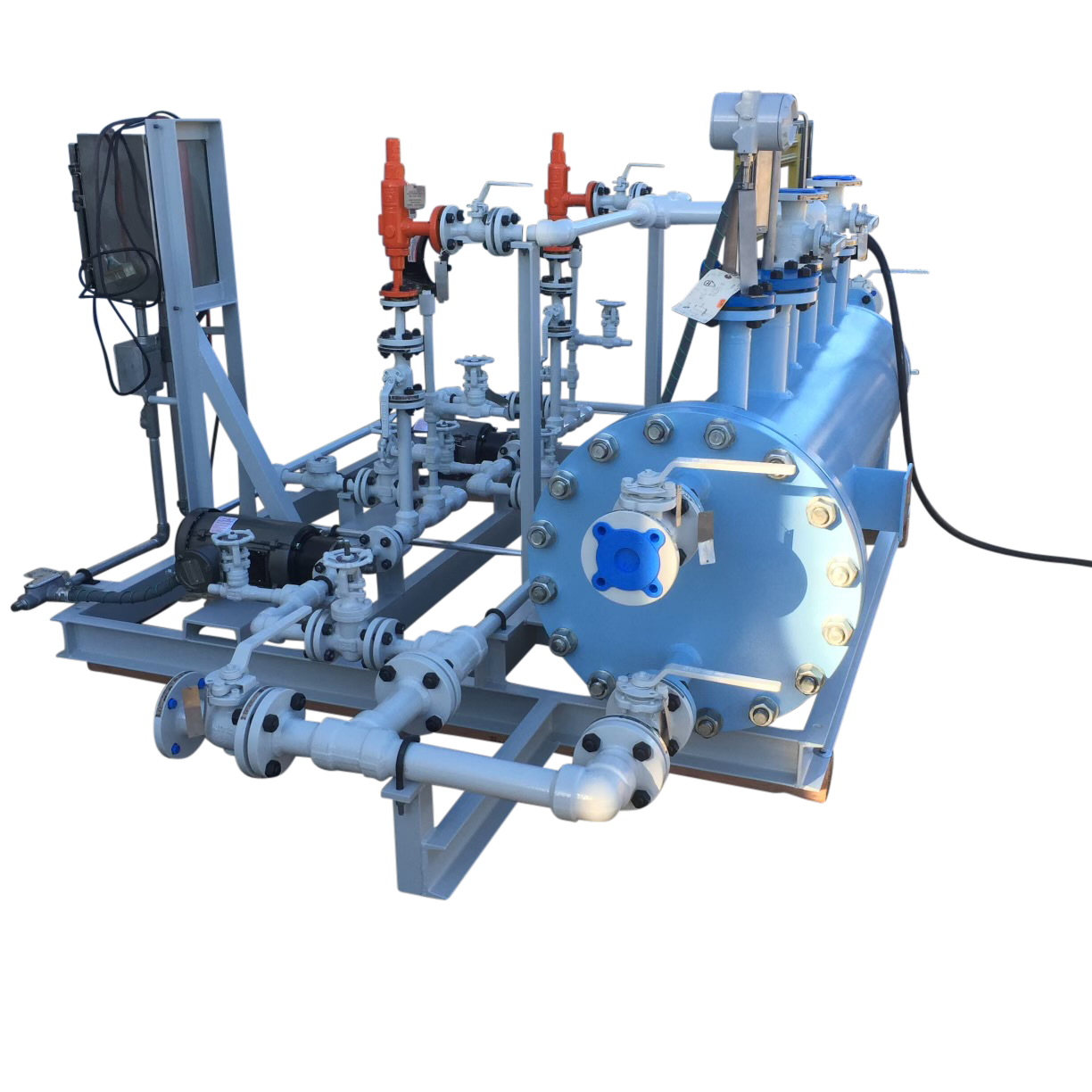

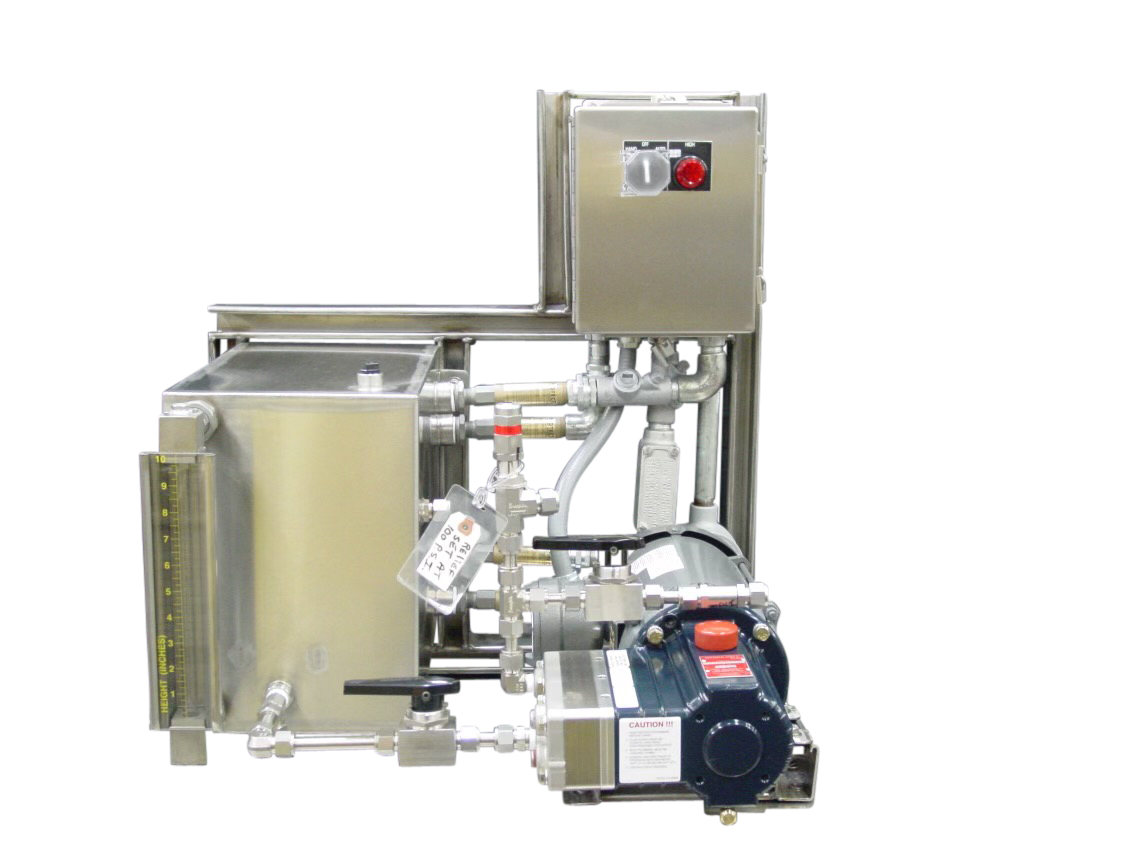

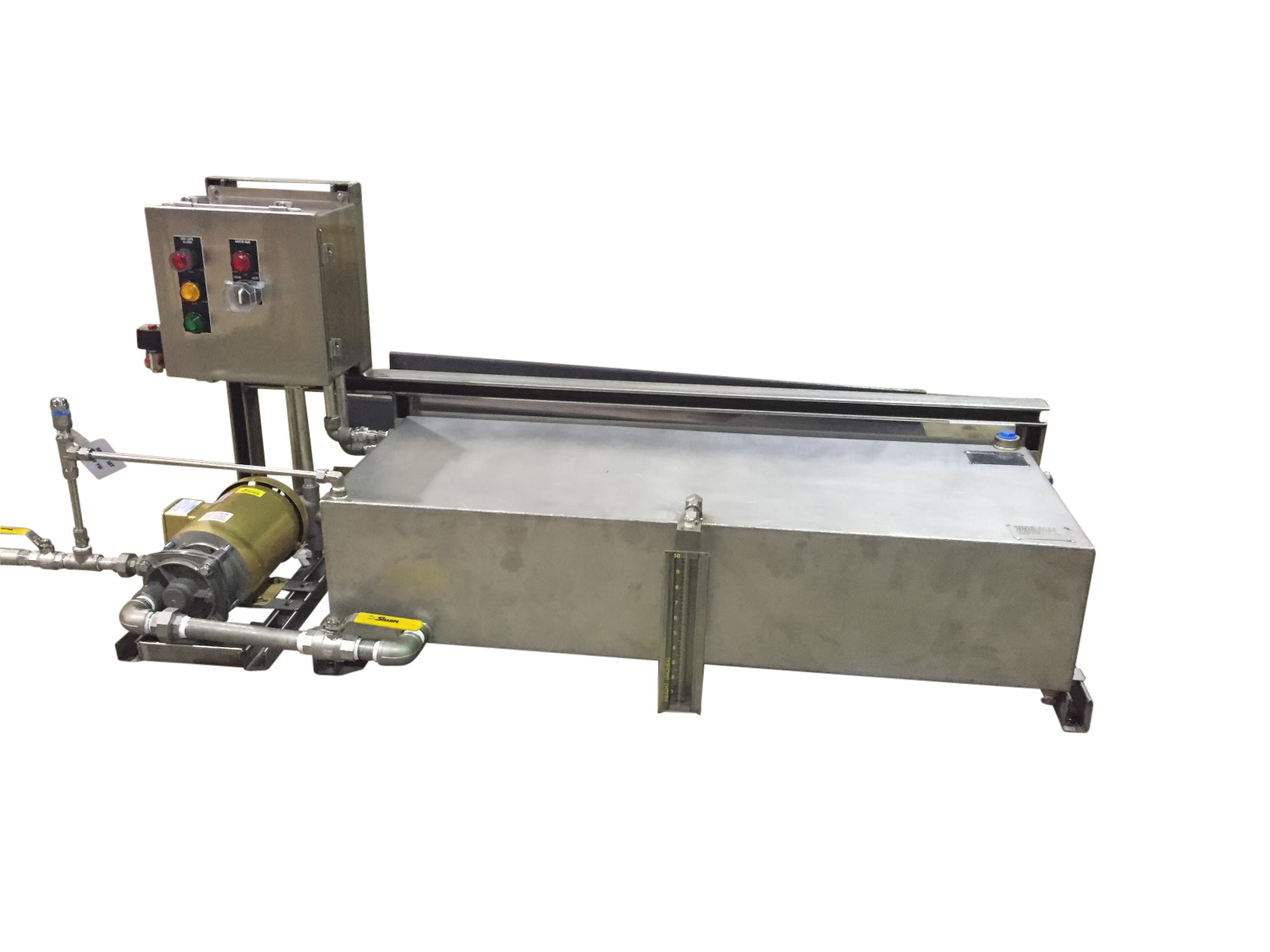

TPE Liquid Recovery Systems are designed specifically to collect process liquid (effluent or spent sample) from analyzers and return this to the process line, or any other suitable location in a fully controlled manner where the process sample is normally not suitable for disposal to sewer or atmosphere.

Applications

TPE Liquid Recovery Systems are ideal for use in applications where it is undesirable to discharge chemicals or hydrocarbons into sewage drains. However, analyzers are often limited in pressure and temperature, so the required pressure reduction means that the spent sample cannot be returned to the process line from which it was taken. A consequence of this is that a sample collection system has to be installed which collects the sample. The liquid sample recovery system allows either natural flow or pressure to drain from the analyzer and the fast loop of the sample conditioning system outlets into the atmospheric recovery tank. The sample is returned to the process using pumps.

Here are some benefits of using these collection vessels

- Spares the environment

- Avoids hazardous situations

- Creates a stable outlet condition for the analyzers

- Costly product is not lost and can be reprocessed by recovering spent samples

Components of TPE Liquid Recovery Systems

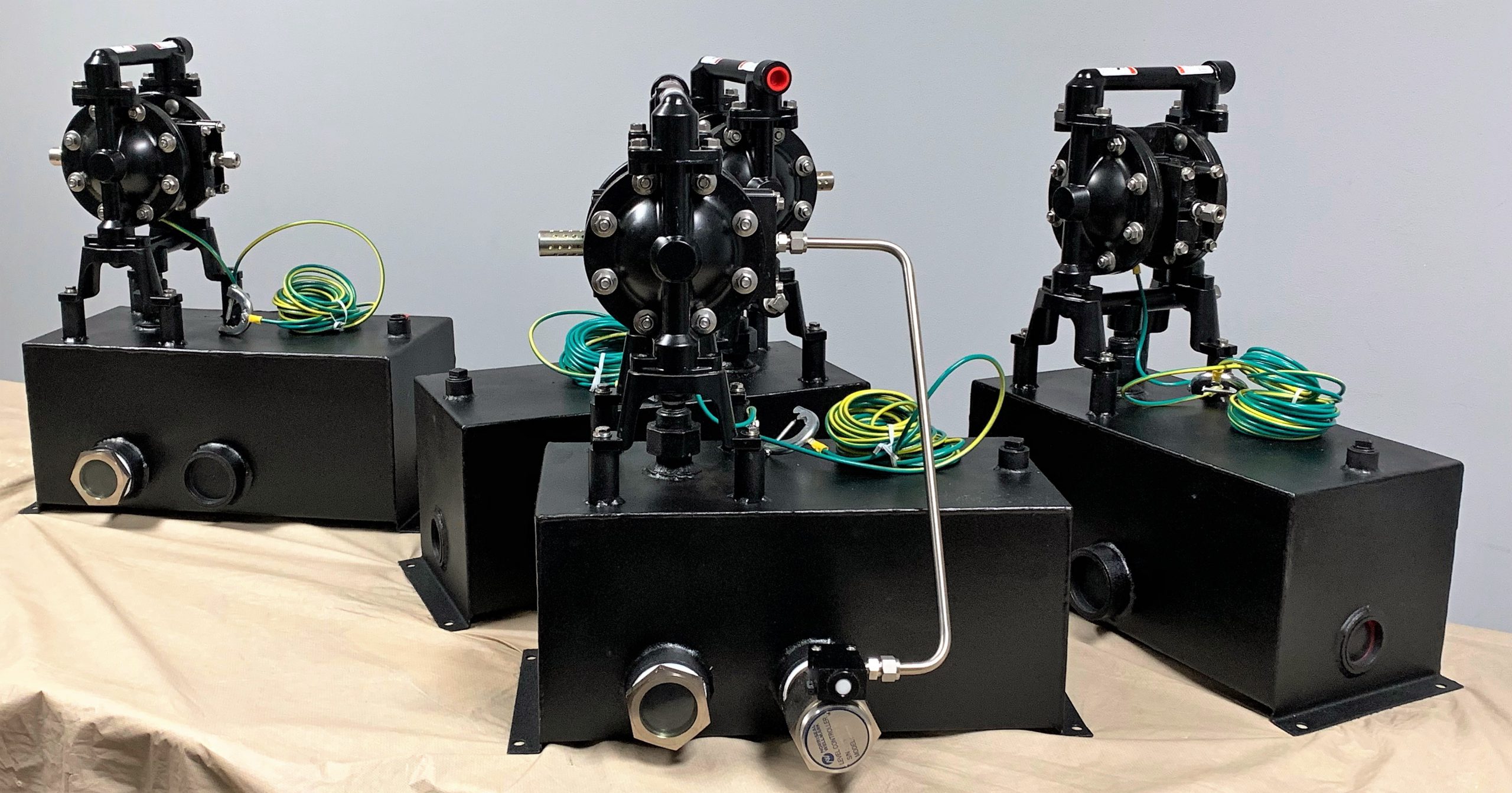

A standard sample recovery system includes supporting rack, recovery tank, level gauge with high/high and low/low alarm level switches, local instruments, single or dual pump ADPE motor driven, valves and local panel with push buttons and selectors for local/ remote control selection and for pump start/stop.

The system is always designed to process return requirements and can handle product characteristics such as pour point, viscosity, density and hazardous area classification. The size and shape of vessel can be adapted to local conditions.

Features

- Efficient recovery and discharge of product back into the process.

- Vent vapor discharge available for vapor emissions to Flare.

- Pump bypass line equipped with a relief valve to prevent overpressure discharge

- Magnetic Type level indicator for visual indication

- Level Low/Low and Level High/High alarm available to trip the entire system

Advantages

- Stable condition at the process analyzer outlet.

- Ideal for use in applications where it is undesirable to discharge hydrocarbons or chemicals into sewage drains

- Recovering your product is one of the simplest ways to increase your profit and reduce costs

- The ability to reduce product waste by assessing how much product is being wasted

- Environmentally friendly operating changes like product recovery can help your organization to “go green”

Types of LRS

There are 2 types of LRS, single line or fast loop

Single Line

- The sample is not returned to the process and can be disposed of properly

- The sample is extracted from the process line and transported to a conditioning system if necessary, and directed to the analyzer before being disposed of via a vent or drain

- Disposal likely won’t pose a problem if the sample is a gas and the full line flow can go to a flare, furnace or stack

- Single-line transport is less common for liquid samples, mostly due to disposal problems

Fast Loop

- Provides rapid responses to process changes by transporting the sample to the analyzer location at high speeds

- Can run at a higher flow rate than a single-line system because most of the flow returns to the process

- Fast loops frequently employ tubing or piping with larger bore to achieve their higher flow rate with less pressure drop

- Used in applications where the process fluid can’t be flared (gas) or drained (liquid) or is too valuable to waste

TPE can build an LRS to suit your needs. Contact us to find out more.