Eclipse

Eclipse

Markets

Typical Applications

Materials of Construction

Magnet: Neodymium in 316LSS welded, Neodymium in Alloy C welded

Gears & Liner: Carbon reinforced PTFE

Shafts: 316LSS, Alloy C

Bearings: Carbon Graphite or Graphite-impregnated Silicon-carbide

O-rings: PTFE

| Feature | Value |

|---|---|

| Industrial Design | Structurally rugged with corosion-resistant materials ensures compatibility with the toughest chemicals |

| Sealless Design | Magnetically driven, sealless design ensures zero leakage and no emission of hazardous chemicals |

| Front-pullout Design | All typical wear components can be easily replaced by removing the front cover only. No need to disconnect piping or motor connections. Reduced pump down-time for repair or scheduled maintenance. |

| Minimal Number of Components | Fewest component gear pump on the market ensures long life and ease of maintenance. |

| Efficiency | Ideally suited for low flow operation where centrifugal pumps perform efficiently and can experience caviation increased radial loads and unstable flow. |

select the green points for more information

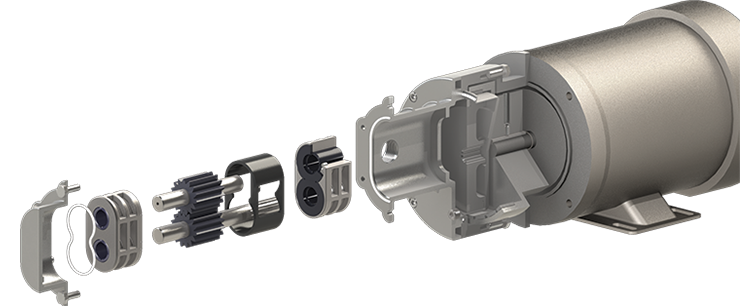

Single Tool Repair

Install your KOPkit® using only one tool

Housing Liner

Patented liner protects housing from wear. Allows as-new performance with the change of a KOPkit®.

Heavy Duty Bearings

Designed with large wear areas to accommodate hydraulic loads. Special materials and patent pending features allow dry-run capabilities.

Containment Can

Resists Heat Damage due to Eddy Currents and Eliminates Leak Paths

Tolerance O-rings

Maintains proper internal clearances, tolerant of axial wear or thermal expansion.

Single Piece Gear/Shaft Assembly

Eliminates retaining rings and keys

Fully Encapsulated Magnets

For maximum corrosion resistance. Spline design allows driven magnet to “float” within the can. The magnet will self-align with no extra fasteners and no axial loads induced on the shaft.

Rigid Pump Base*

Corrosion resistant and robust for optimum pump support in harsh environments. Slotted holes fit multiple motor frame feet for easy retrofitting in existing installations

**Rigid Pump Base available on E75 and 125

**Universal Flanges available on E75 and 125