Eclipse 12

Eclipse 12

- Approximate Shipping Weight: 10.0 lbs. (4.5 kg.) less motor

- Min Fluid Temperature: -40°F (-40°C)

- Fluid pH Range: 0-14

- Approximate Weight: 10.0 lbs. (4.5 kg.) less motor

- Bearing Type: Internal Sleeve

- Magnet: Neodymium Encapsulated Virgin ETFE

- Solution Description: Transfer or Metering (Dosing)

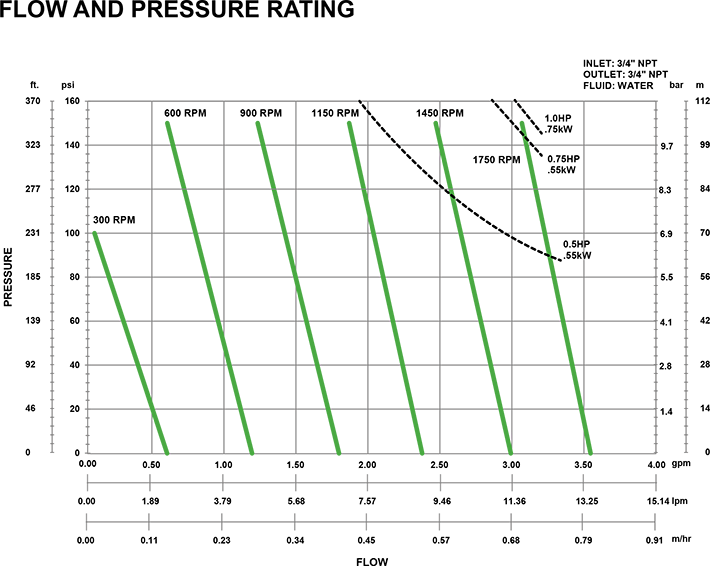

- Turndown Ratio: SEE FLOW CURVES

- Casing Housings: PVDF, Optional Carbon-reinforced ETFE

- Max Speed: 1750 rpm

- Theoretical Displacement: 0.226 US gal/100 rev. (8.6 cc/rev.)

- Drive Shaft Diameter: 0.437"

- Min System Pressure: .1mm Hg (abs)

- Max Allowable Working Pressure: up to 200 psig (14 bar)

- Motors: 1750 RPM, 60 Hz (1450 RPM, 50 Hz)

- Motor Power: 1 but is influenced by operating differential pressure and fluid viscosity

- Motor Frame: NEMA: 56C, 143/145TCIEC: 63 to 80 B3/B14 Face

- Seat O-Rings Available: FKM, EPDM, Kalrez®

- Drive Idler Gears: Carbon Reinforced PTFE/External Spur Gear

- Shafts: Alumina Ceramic

- HP Required: 1 but is influenced by operating differential pressure and fluid viscosity

- Pump Controls Links: MPCv

- Bearings: Carbon Graphite or Graphite-Impregnated Silicon-Carbide

- Port Size and Type: .75 inch FNPT or ISO 7-1, Optional Kit Thread In, Face Static Seal 1.0" 150# ANSI Flange, DIN 15/20

- Bearing Lubrication: Process fluid

- Max Differential Pressure: Carbon Bearings: 100 psi (6.89 bar), Silicon Carbide Bearings: 150 psig (10 bar)

- Product Options: Bearing flush

BROCHURES Eclipse Brochure

Eclipse Brochure

FLOW CURVES Eclipse Series Flow Curves 02-125

Eclipse Series Flow Curves 02-125

TECH SHEETS Eclipse 12 Non-metallic Data Sheet

Eclipse 12 Non-metallic Data Sheet  Eclipse Non-metallic Value

Eclipse Non-metallic Value  Metering with Gear Pumps

Metering with Gear Pumps

IOMS Eclipse IOM

Eclipse IOM

Features

- All wetted components are completely non-metallic, not lined

- Pump housings and gears are made of engineered composites, magnetically driven, and require no mechanical seals

- Zero leakage, no emissions of hazardous or regulated chemicals

- Fewer parts and material options means simplified ordering and inventory

- Front pull-out design - makes for easy service and maintenance in place

- Pre-defined KOPkits® allow for easy ordering and kitting of all necessary parts to bring the pump back to factory performance

- Engineered composite fluoropolymer provide superior chemical resistance, lighter weight, shorter lead-times

- Pump is bidirectional-can be operated in either direction

- Modular design allows for the pump ports to be mounted in 45° increments (to a full 360°, vertical, horizontal, or any configuration imaginable)